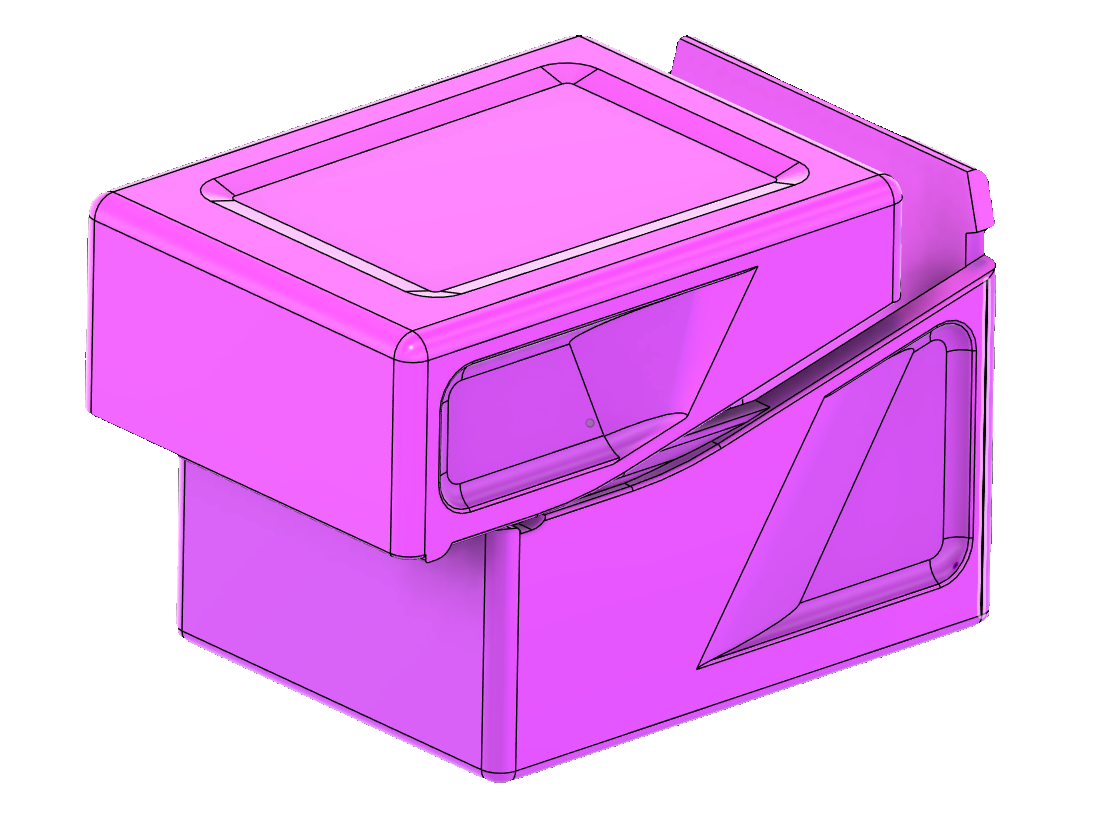

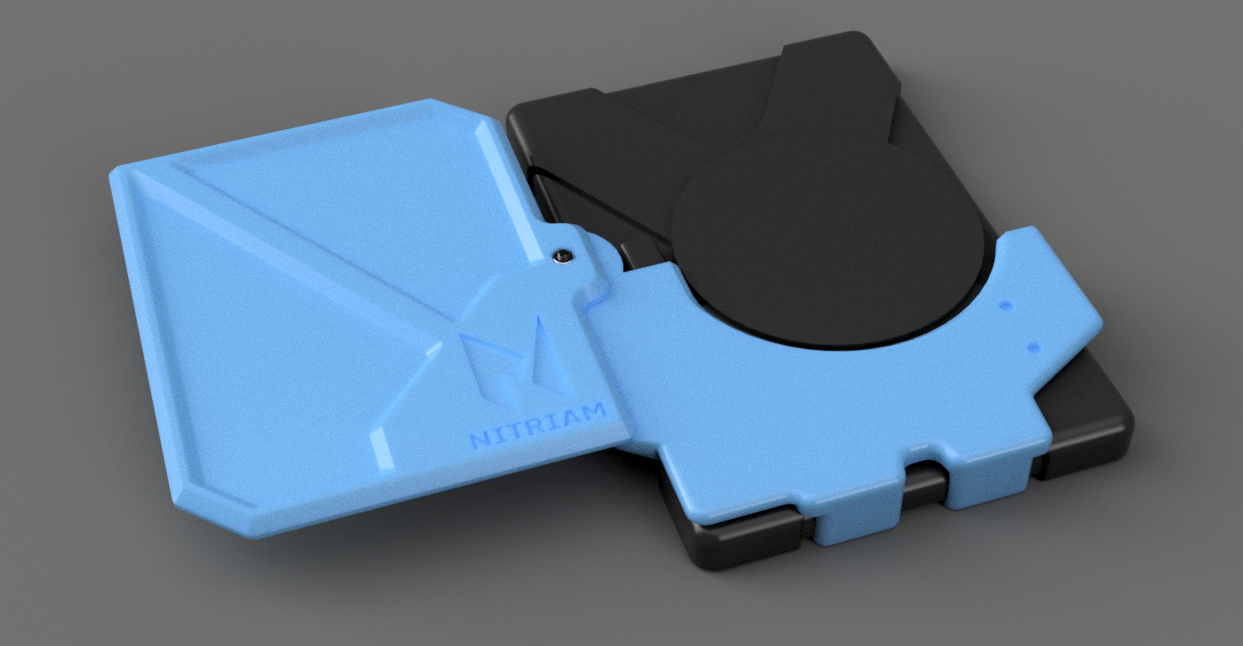

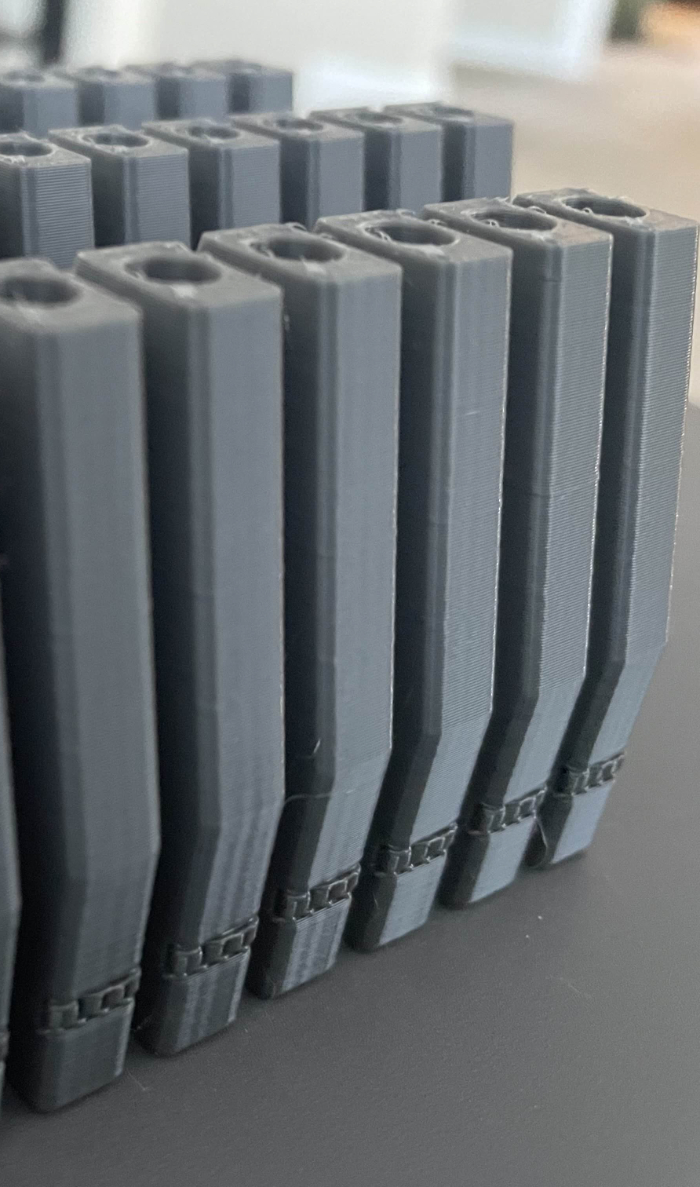

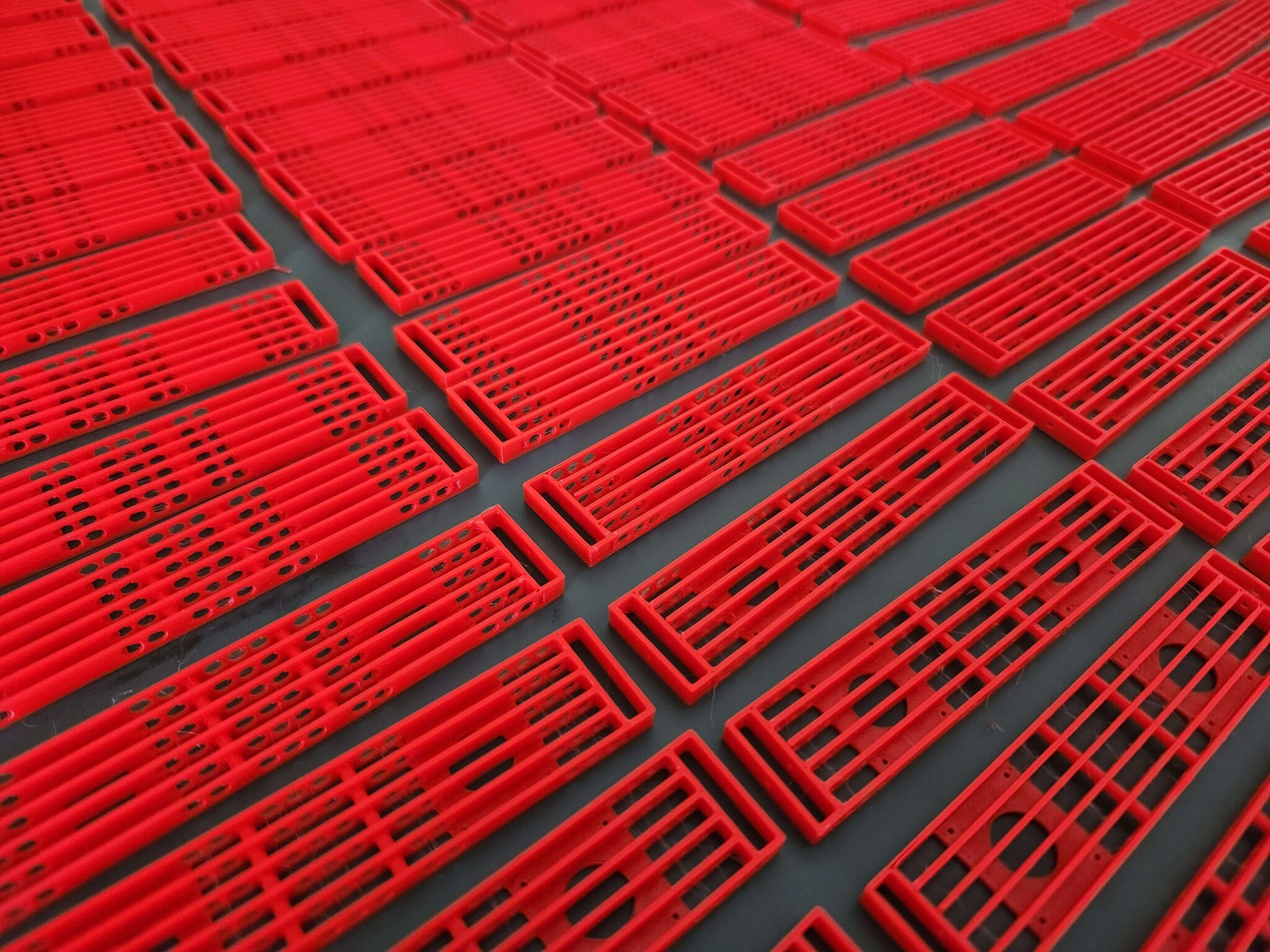

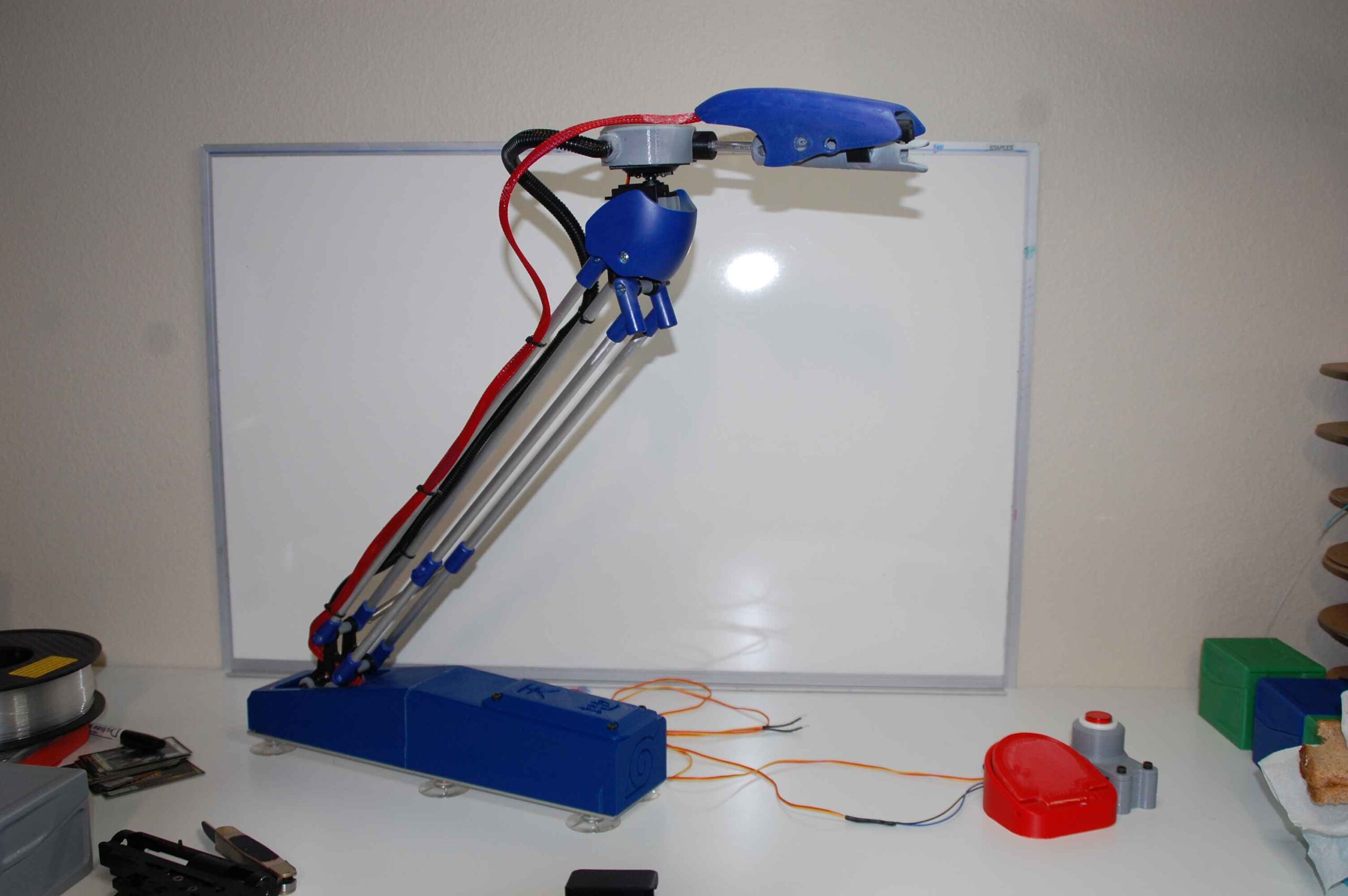

We offer small-scale 3D print manufacturing services for custom parts, prototypes, and resale-ready products. With experience producing batches of functional and cosmetic parts, we ensure consistent quality, and match requested standards.

- Small-Batch Production – Produce quantities ranging from one-off parts to repeatable short runs for resale or internal use, with quick production and turn around time.

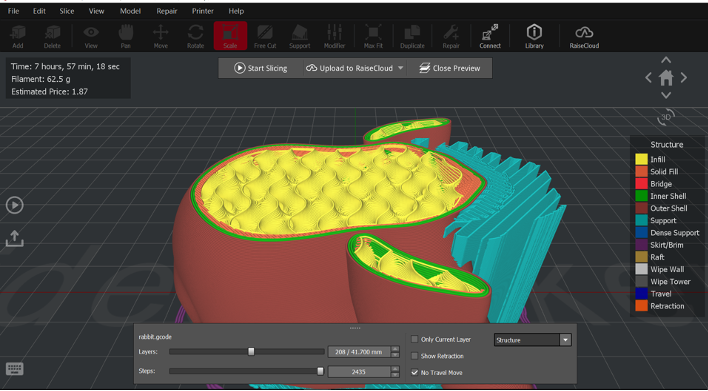

- Material Options & Recommendations – Print in PLA, ABS, PETG, TPU, and more depending on your requirements. We can also recommend certain materials based on the parts and design given.

- Quality Control – Parts are checked for dimensional accuracy, visual or functional defects, and consistency before delivery or packaging, further checks and standards can be requested as well.